Once again it is time to pull apart the hubs and clean and repack the bearings. At the same time, I give the brakes a good cleaning. It's a pretty straight forward job, but it does take a bit of time, as you have to jack up the Alto, pull everything apart, clean and repack, then put it all together again. I imagine at some point I will just have it done somewhere, but until that time comes, it will be one of those spring jobs I do.

I noticed there was a fair amoint of brake dust on the inside of the rims, so I suspect I have been re-adjusting the shoes perhaps a tad to close. This time I will make a point of leaving them backed off just a little bit more. I can always give them a fine tune if I find the electric brakes are not grabbing enough. Once I got the hubs off, everything looked pretty good. The grease is still bright blue, with no sign of discolouring of that icky milky consistancy when water has started to get mixed in.

Gave the drums and the shoes a good cleaning, then pulled the back seal, cleaned both the bearings, had a real close look for any pitting or excessive heat scorching, but all looked good. Repacked the bearings, greased up the races, then put the hubs back on. Tightened up as per the Dexter Service Manual, and we were done. Checked the brake adjustment, then headed over and did the other side.

I'm rotating the tires, so the service side tire now becomes the spare. The inside of the rims were in bad need of cleaning to get rid of the brake dust, but afterwards, they looked great. Getting the spare tire back in place was probably the part of the process thst I was least looking forward to. The way it hangs under the tongue is a very nifty setup, but a serious pain in the ass to re-install. There had to be a simpler way to do this other than brute effort. After staring at it a bit, which is an activity that has always served me well in the past, I figured that whatever method used to help the process had to utilize gear that would be with us at all times.

Looking in the trunk, I spied the Anderson Levellor, and the wheel chocks. I figured if I could get one side propped up high enough, it would be easy to just raise the other side and start threading on the support bar. Sure enough, I was able to use the levellor and chock to get the one side almost totally in place, then I easily lifted the other side up, held it in place with my knee, then secured the whole thing. Easy peasy.

I think we could probably go three years between repacks, based a lot on the current yearly milage we do. Will we go the three years, hard to say. It is nice to know that the bearings are in good shape.

I noticed there was a fair amoint of brake dust on the inside of the rims, so I suspect I have been re-adjusting the shoes perhaps a tad to close. This time I will make a point of leaving them backed off just a little bit more. I can always give them a fine tune if I find the electric brakes are not grabbing enough. Once I got the hubs off, everything looked pretty good. The grease is still bright blue, with no sign of discolouring of that icky milky consistancy when water has started to get mixed in.

Gave the drums and the shoes a good cleaning, then pulled the back seal, cleaned both the bearings, had a real close look for any pitting or excessive heat scorching, but all looked good. Repacked the bearings, greased up the races, then put the hubs back on. Tightened up as per the Dexter Service Manual, and we were done. Checked the brake adjustment, then headed over and did the other side.

|

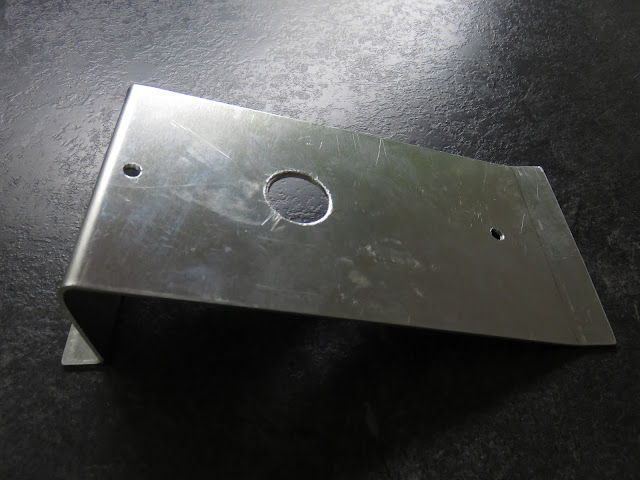

| front bearing ready to go... |

|

| a lot cleaner now...and still in real good shape |

I'm rotating the tires, so the service side tire now becomes the spare. The inside of the rims were in bad need of cleaning to get rid of the brake dust, but afterwards, they looked great. Getting the spare tire back in place was probably the part of the process thst I was least looking forward to. The way it hangs under the tongue is a very nifty setup, but a serious pain in the ass to re-install. There had to be a simpler way to do this other than brute effort. After staring at it a bit, which is an activity that has always served me well in the past, I figured that whatever method used to help the process had to utilize gear that would be with us at all times.

Looking in the trunk, I spied the Anderson Levellor, and the wheel chocks. I figured if I could get one side propped up high enough, it would be easy to just raise the other side and start threading on the support bar. Sure enough, I was able to use the levellor and chock to get the one side almost totally in place, then I easily lifted the other side up, held it in place with my knee, then secured the whole thing. Easy peasy.

|

| works like a charm |

I think we could probably go three years between repacks, based a lot on the current yearly milage we do. Will we go the three years, hard to say. It is nice to know that the bearings are in good shape.